Have you ever wondered what goes into creating a pair of custom-made shoes? The intricate process behind crafting a shoe that perfectly fits your unique style and comfort is nothing short of fascinating.

From hand-selecting the finest materials to meticulously stitching every detail, each step contributes to the artistry and quality that goes into these personalized masterpieces.

In a world where mass production dominates the market, there is something truly special about owning a pair of shoes that has been crafted exclusively for you. It's a way to express your individuality and stand out from the crowd. But the question remains: how does it all come together?

Get ready to be amazed as we uncover the secrets behind this intricate process and discover the extraordinary attention to detail that makes custom-made shoe craftsmanship an art form in its own right.

So buckle up, because this behind-the-scenes adventure is about to take you on a mesmerizing ride you won't want to miss!

How Are Custom-Made Shoes Crafted?

Have you ever wondered what goes into creating a pair of custom-made shoes? The intricate process behind crafting a shoe that perfectly fits your unique style and comfort is nothing short of fascinating.

From hand-selecting the finest materials to meticulously stitching every detail, each step contributes to the artistry and quality that goes into these personalized masterpieces.

In a world where mass production dominates the market, there is something truly special about owning a pair of shoes that have been crafted exclusively for you. It's a way to express your individuality and stand out from the crowd. But the question remains: how does it all come together?

Get ready to be amazed as we uncover the secrets behind this intricate process and discover the extraordinary attention to detail that makes custom-made shoe craftsmanship an art form in its own right.

So buckle up, because this behind-the-scenes adventure is about to take you on a mesmerizing ride you won't want to miss!

How Are Custom-Made Shoes Crafted?

Creating custom-made shoes is a fascinating process that involves several steps. Let's walk through each of them together!

1. Consultation and Understanding of Customer Needs

When it comes to the bespoke shoe-making process, one crucial step is the consultation and understanding of customer needs. This stage is where the magic begins, as it allows the shoemaker to connect with the customer on a personal level and create a truly tailored experience.

During the consultation, the shoemaker engages in friendly and insightful conversations with the customer to grasp their desires, preferences, and expectations. This is a time to build rapport and establish trust, ensuring that the customer feels comfortable and confident in expressing their unique requirements.

For example, imagine a customer who has always dreamt of owning a pair of elegant, handcrafted leather brogues. During the consultation, the shoemaker takes the time to understand the customer's shoe measurements and style preferences. They delve deeper into details like the type of leather finish, color options, sole thickness, and even the intricate design patterns the customer envisions.

By actively listening and asking relevant questions, the shoemaker gains valuable insights into the customer's needs, translating their vision into a tangible masterpiece.

Another example could be a customer who seeks a handmade shoe for a specific occasion, such as a wedding or a formal event. In this case, the consultation becomes an opportunity for the shoemaker to understand the event's theme, the customer's outfit, and the desired level of comfort for a long day of celebration.

The customer may have specific requests, such as incorporating embellishments, personalized monograms, or unique materials to match their attire. The shoemaker's ability to truly comprehend these needs and guide the customer through the process is vital in delivering a memorable and satisfying experience.

2. Exploring Different Material Options for Shoe Construction

Selecting the appropriate materials is of utmost importance when it comes to designing customized men's shoes. It is a key factor in striking the ideal harmony between style and practicality. Different components of the shoe, including the upper, lining, insole, outsole, and others, can be made using a diverse range of materials.

Let's discuss some examples of different materials that can be considered:1. Leather: Leather has the greatest popularity among shoe manufacturers due to its durability, flexibility, and breathability. It comes in various types such as full-grain, top-grain, and suede, each with its own distinct look and feel. Leather can be dyed in numerous colors and finishes, offering a wide range of customization possibilities.

2. Exotic leathers: For a more luxurious and distinctive touch, exotic leathers like alligator, crocodile, ostrich, or snake skin can be used. These materials not only provide a unique aesthetic but also offer exceptional durability and texture.

3. Suede: Suede is a type of leather with a napped finish, which adds a soft and velvety texture to the shoe. It is often used for casual or dress-casual shoes, providing a more relaxed and stylish look.

4. Canvas: Canvas is a lightweight and breathable fabric commonly associated with casual or summer shoes. It is versatile, available in various colors and patterns, and can be an excellent choice for creating casual and comfortable shoes.

5. Synthetic materials: Synthetic materials like nylon, polyester, or microfiber can be used as alternatives to leather. These materials offer advantages such as water resistance, easy maintenance, and affordability. They are often used in athletic or outdoor footwear where specific performance properties are required.

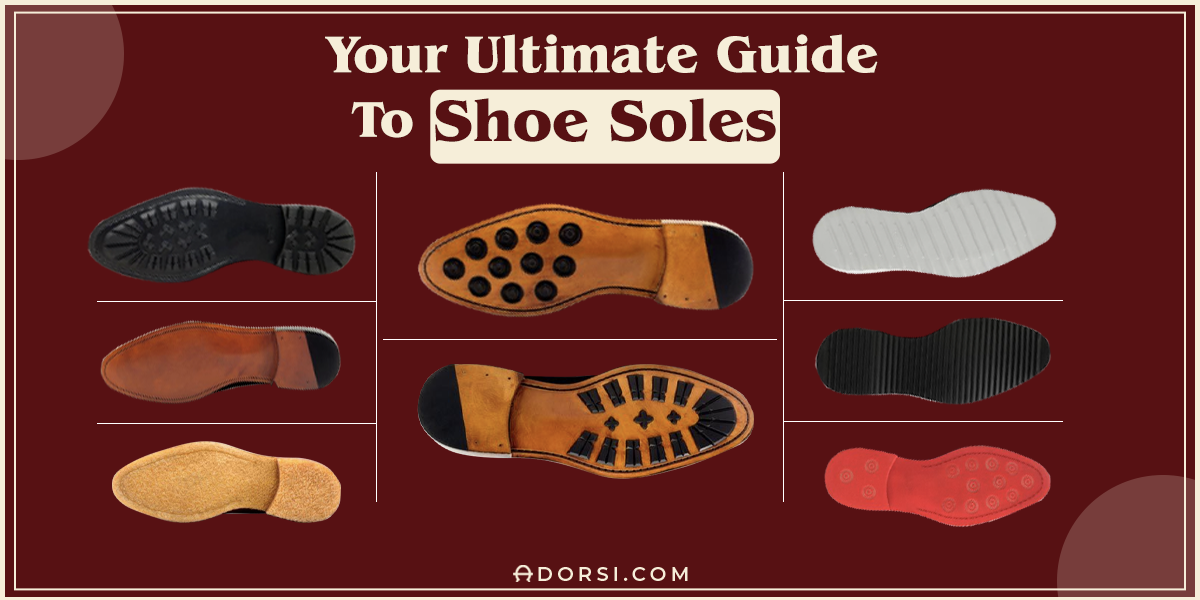

6. Rubber or TPU (thermoplastic polyurethane): These materials are commonly used for shoe soles to provide cushioning, shock absorption, and traction. They offer durability and flexibility while ensuring comfort and stability during wear.

7. Cork: Cork is a unique material that can be used for insoles or footbeds. It provides excellent shock absorption, moisture-wicking properties, and a natural contour that molds to the wearer's foot over time.

These are just a few examples of the many material options available for custom men's shoe construction. Exploring different materials allows shoemakers to create shoes that not only reflect the individual style of their customers but also offer the desired comfort, durability, and performance.

3. Pattern Creation

Pattern creation involves designing and developing the blueprint or template of the shoe. Skilled craftsmen or designers work on creating patterns that capture the specific style, design, and measurements required for each custom men's shoe. This step requires a deep understanding of shoe anatomy, proportions, and the individual's foot shape.

For example, when creating a pattern for a classic Oxford shoe, the craftsmen would carefully consider the placement of the vamp, quarters, and eyelet facings. They would also take into account the size and positioning of the toe cap, the throat line, and the overall silhouette of the shoe.

Once the pattern is finalized, we can move to the next step.

4. Cutting the Chosen Materials According to the Pattern

Cutting involves carefully tracing the pattern onto the chosen material and precisely cutting out the individual components of the shoe. Expert craftsmen use specialized tools like knives or laser cutters to ensure clean and accurate cuts.

Let's consider a scenario involving the creation of a sophisticated dress shoe for men, specifically a sleek and stylish black Oxford shoe. The pattern for this particular design encompasses various essential components, including the upper (which forms the main body of the shoe), the lining, and additional elements like the tongue and heel counter.

Highly skilled artisans would meticulously transfer the pattern onto the selected black leather, paying close attention to optimize material utilization and minimize wastage. Using precise cutting tools such as leather knives or industrial scissors, they would meticulously cut along the traced lines, ensuring clean and sharp edges. Consistency in shape and size across each piece is paramount, guaranteeing a flawless fit and an aesthetically pleasing final outcome.

Once the components are cut, they are ready to be assembled by skilled shoemakers, who will stitch them together, attach the sole, and complete the finishing touches to create a bespoke men's shoe that matches the client's preferences and measurements.

5. Lasting

During the lasting process, the shoe upper is carefully pulled over a shoe-shaped form called a last. The last serves as a mold that provides the shoe with its desired shape, size, and proportions.

Skilled craftsmen use specialized stretching and pulling techniques to ensure a proper fit and eliminate any wrinkles or excess material. This step is crucial in achieving a comfortable and well-fitted final product.

Choosing the Right Stitching Method

Shoe stitching is a crucial part of the shoemaking process that adds both functional and aesthetic value to the final product. It involves joining different pieces of leather or other materials using various stitching techniques.

There are several types of common shoe construction methods used in custom men's shoemaking. Let's explore a few examples:

1. Goodyear Welt Stitch: This technique is named after Charles Goodyear Jr., an esteemed American inventor who discovered the process of vulcanized rubber, which revolutionized the production of shoes. Renowned for their exceptional durability and repairability, Goodyear welted shoes are crafted by stitching the upper, insole, and welt together, resulting in a robust and long-lasting bond.

The stitches are made in a way that they are concealed between the insole and the outsole, providing excellent water resistance and flexibility. Goodyear welt stitching is often seen in a wide range of shoe styles including dress shoes or boots.

2. Blake Stitch: The Blake stitch is another common technique used in custom shoemaking. It involves stitching the outsole directly to the shoe's upper, creating a sleek and streamlined look. Blake-stitched shoes have excellent flexibility and comfort. Blake stitching is often found in Italian-style dress shoes or loafers.

3. Norwegian or Storm Welt Stitch: This shoe construction method is specifically designed to enhance the durability and strength of footwear intended for demanding and rugged environments. Norwegian welt stitching involves attaching the upper, insole, and welt using a double row of stitching that runs along the edge of the shoe's outsole.

Norwegian stitching is often seen in robust, outdoor-oriented double-stitched shoes like rugged shoes and hiking boots.

4. Blake rapid stitching: Blake Rapid Stitching is a footwear construction method that combines elements of the Blake and Goodyear stitching techniques. It involves stitching a midsole along the bottom of the lasted insole to provide a stable platform for the outsole. The midsole is then attached to the upper using a high-speed stitching machine.

One of the advantages of Blake Rapid Stitching is that it allows for the easy replacement of the sole unit. This means that the outsole can be removed and replaced with a different sole as needed.

Shoes constructed using the Blake Rapid Stitching method are known for their sturdiness and durability. The additional midsole provides extra support, making these shoes suitable for rugged or heavy-duty use. Additionally, the construction method can contribute to the waterproofing of the shoes.

It's important to note that the choice of construction method, whether Blake Rapid Stitching or another technique, depends on factors such as the desired level of flexibility, cost, and specific shoe requirements.

5. Strobel stitching: This technique involves stitching the upper fabric directly to a flexible insole, typically made of foam or other lightweight materials. This technique creates a seamless and flexible construction, allowing the shoe to be more lightweight and comfortable. Strobel stitching is often found in athletic shoes, casual sneakers, and other types of lightweight shoes.

The art of shoe stitching requires skill, patience, and precision. Each stitch plays a crucial role in ensuring the longevity and quality of the shoe.

6. Sacchetto stitching: The term "sacchetto" is derived from the Italian word for "bag" or "sack," as the method involves creating a soft, bag-like structure for the shoe's interior.

In the sacchetto stitching method, the shoe's upper is stitched directly to the lining material, usually made of soft leather or soft textile. The stitching is done inside-out, creating a "bag" that envelops the foot when the shoe is turned right-side out. This technique eliminates the need for additional insoles or midsoles, resulting in a lightweight and flexible shoe.

The sacchetto construction offers several advantages. The absence of stiff components between the upper and the lining allows for a close and glove-like fit. The seamless interior reduces friction and provides enhanced comfort, making it suitable for those with sensitive feet.

Additionally, the flexibility of the sacchetto construction allows for natural foot movement and greater breathability.

It's important to note that sacchetto stitching is commonly used in high-quality dress shoes, loafers, and other styles where comfort and a refined appearance are valued.

Finishing

After the sole is attached, the shoe enters the finishing stage. This step focuses on refining the appearance of the shoe and enhancing its durability. Finishing techniques can vary widely and depend on the desired aesthetic and quality of the final product.

Common finishing processes include sanding, buffing, and polishing the surfaces of the shoe to achieve a smooth and even texture. Dyeing and coloring may also be applied to achieve the desired color or shading.

Additional treatments, such as waterproofing or adding protective coatings, may be applied to improve the shoe's functionality and longevity. Any desired embellishments, such as decorative stitching, hardware, or logos, may also be added during this stage.

Quality Control

Once the finishing stage is complete, the custom-made shoe undergoes a thorough quality control inspection. Skilled inspectors carefully examine the shoe for any stitching or construction flaws, ensuring that all seams are secure and there are no loose threads.

They also check the overall comfort and fit of the shoe. Any issues or imperfections discovered during this inspection are addressed and corrected to meet the desired standards of quality.

Shoemaking is an art form that combines skill, creativity, and attention to detail. The dedication and expertise of shoemakers are evident in each carefully crafted pair.

Whether it's a classic leather oxford, a trendy sneaker, or a Golf shoe, the world of shoemaking offers a vast array of choices to suit every style and occasion. So, step out with confidence, knowing that your shoes have been crafted with passion and care, ready to accompany you on your daily adventures.

Frequently Asked Questions (FAQs)

1. How do I find a reputable custom shoemaker?

Finding a reputable custom shoemaker can be a daunting task, but look no further than Adorsi. With a team of professional entrepreneurs and expert shoemakers at the helm, Adorsi is committed to delivering exceptional craftsmanship and ensuring customer satisfaction. Their proactive, talented, and highly competent workers strive to create real value in the market, setting them apart as a reliable choice for custom-made shoes.

2. How long does it take to make a custom pair of shoes?

The time required to make a custom pair of shoes can vary depending on several factors, including the complexity of the design, the availability of materials, and the workload of the shoemaker. Typically, it can take several weeks to a few months for the entire process, including consultations, measurements, pattern creation, production, and final adjustments.

3. Can I choose the materials used in my custom shoes?

At Adorsi, you have the freedom to select from a diverse range of high-quality materials. From different types of leather to fabrics and specialty materials, we offer a variety of options to suit your preferences and create a truly personalized pair of shoes.