Unique footwear will always set you apart from the crowd. Therefore, knowing the smallest details of your shoes can dramatically change your perspective and inspire you to have your own style.

Shoe lasts are a crucial part of the shoemaking process since they affect not only the measure, fit, and comfort of shoes, but also their style and appearance.

And here, you’ll know all about shoe molds, allowing you to select the fitting shoes that can elevate your style and bring a touch of elegance to your own wardrobe.

What Are Shoe Lasts?

To put it simply, a shoe last is a wood, metal, or plastic template that shoemakers use to shape shoes. It is uniquely tailored to fit the leather when it is stretched over it in the shoemaking process.

In other words, it is the mold and the attachment point that binds the upper, sole, and other accessories together in the shoe manufacturing process.

So, a last's design influences the style of all the other parts of a shoe design.

For instance, the last determines the shape of its outsole, a heel pitch must match a last's shank curve, and so on.

Even though there are a variety of last styles and sizes available, its precise shape depends on the kind of footwear it will be used to make.

Why Is A Last Important?

If you are looking to get a high-quality pair of loafers, then there are some important factors to consider before buying them.

So, let’s break down these factors and find out how lasts play a vital role in each one of them.

1. The Last Size

Since your feet have specific dimensions and measurements, getting a tailored mold will end up with custom shoes that perfectly fit your size.

2. Comfortability

You want your footwear to be comfortable so that you can wear it for long hours without any discomfort or pain.

Well, hand-lasted footwear is actually fabricated to copy your feet and fit your measurements so you get the most comfortable fit possible.

3. Unique Style

As a gentleman, you know the true value of wearing unmatchable loafers, especially when it adds to your unique style a taste of simplicity and sophistication.

By handpicking the lasts, shoemakers pay careful attention to the finishing details and the materials to get the desired look by the end of the shoemaking process.

4. Different Looks

You want footwear that gives you the confidence to be yourself at any time, whether it’s a classical work look or an exquisite evening look.

Well, as lasts are critical in the whole process of footwear design, how they look determines how the final shape of the loafer will appear.

Last Materials

1. Wooden Lasts

Wood is one of the finest materials that last makers use to create strong molds.

An experienced shoemaker uses a person's feet measurements to create a wooden last that fits perfectly. They usually use a hard type of wood (such as maple) to shape a last.

And since wooden lasts are easily customizable, shoemakers can use their specific hand tools and knives for bespoke shoemaking.

2. Plastic Lasts

Last makers also use plastic blanks to create different footwear forms.

Those kinds of lasts are adjustable as they are easy to reshape for fitting tests, and can create different styles for your bespoke shoe.

3. Aluminum Lasts

Aluminum lasts are also very common in shoe construction. They need high-temperature ovens and are easy to recycle.

Often, shoe manufacturers use aluminum lasts for creating snow boots and molding soles.

Shapes of Lasts

1. Straight Lasts

Straight lasts are exactly what their name suggests.

In a straight last shoe, the line at the bottom from the heel to the toe is symmetrical. These lasts are usually common in athletic shoes and motion-control footwear.

2. Semi-Curved Lasts

To differentiate the semi-curved lasts from the other ones, you can notice a slightly inward curve at their insole.

Often stability and neutral shoes have these semi-curved molds.

3. Curved Lasts

Molds with a curve lasted sole have a slight "C" shape, meaning the heel to great toe curves in a concave fashion.

Such molds are light so you can find them in lightweight shoes and racing flats.

The Most Common Last Types

1. Pump Lasts

This type of lasts is the most common one and can generate many other footwear types.

Some examples of pump lasts are Classic pumps, T-strap pumps, Peep toe pumps, Mary-Jane pumps, and D'orsay pumps.

2. Moccasin Lasts

Moccasins have a unique pattern since they are cut together to create one piece with the insole overlapping the bottom and sewn with the tongue on the front.

3. Molds for Loafers With Laces

The instep of these shoe lasts is curved to fit the instep of the feet better.

Oxfords and Derbys usually have these molds.

4. Boots With Zipper

These shoe lasts are just what they sound like as you can do ankle boots or high boots or other types of boots with zippers.

5. Boots Without Any Fastening

Lasts of these boots are wider in both the instep and the back part of the ankle.

6. Cowboy Boot Lasts

Cowboy boot lasts are slightly different from ordinary boots. You can find most of the work done in the boots' unique decorations.

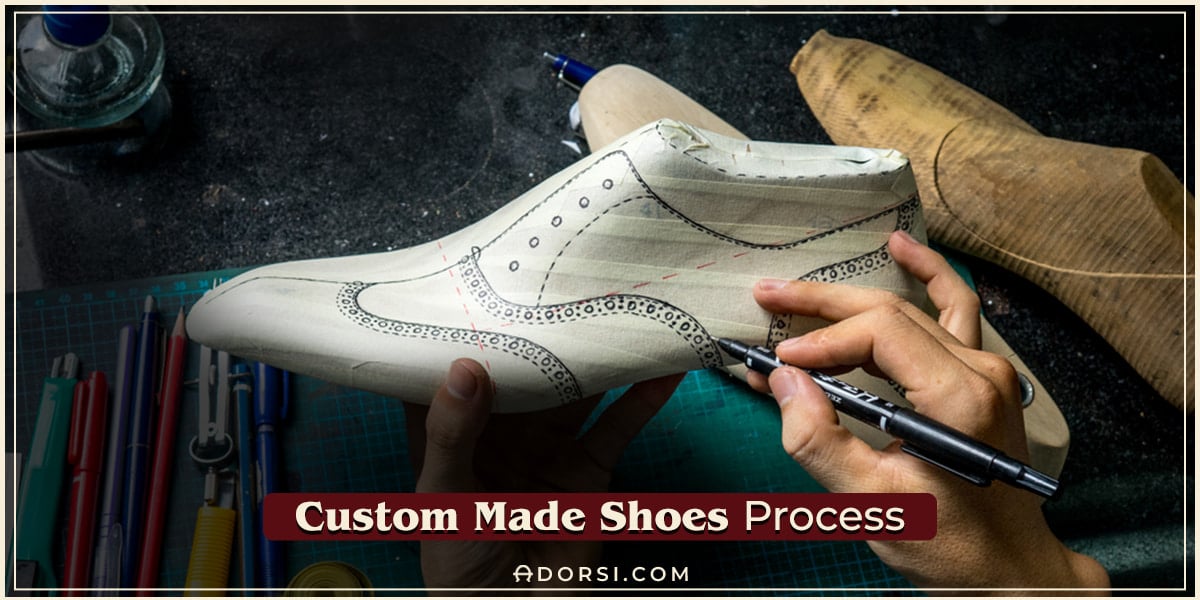

Lasts Construction Process

The method of attaching the upper to the midsole is called the lasting or lasts construction process.

In this process, you can see that bespoke shoes can have different lasts options such as board last, slip last, strobel last, and other ones.

The importance of the last construction is that it affects the stiffness and flexibility of your shoe design.

Frequently Asked Questions (FAQs)

1. Why does every footwear company have different lasts?

As we said previously, there are different types of lasts according to many aspects such as sizes, materials, shapes, and types. Therefore, lasts will differ among different companies.

Handmade lasts can offer personalized fitting and details to get an exclusive design, unlike others. You can see the reasons why choosing custom-made footwear is preferable here.

2. How does a company decide on a last?

Companies decide on a footwear mold depending on the mission it is made for.

This means that a boot last is different from a pump last which is different from a loafer, and so on.

3. Is a last exactly the same as human feet?

A last is not similar to the human foot because the human foot has a complex structure and shape. The last is designed to make sure that you have a flawlessly finished shoe.

Here are a few points that can simply summarize the difference.

- The last surface is smooth and firm, whilst the foot shape is asymmetrical and has distinct surfaces.

- Lasts have a heel pitch while the human anatomy doesn't.

- Lasts have extra room so it's more comfortable when you're practicing your favorite day-to-day activities, such as walking, juggling, running, or even dancing.

- Most lasts don't have individual toes like the feet although the length above the last helps with different human toes shapes.

At ADORSI, we make our lasts to mirror the structure of your feet. That way, you can have your bespoke shoes perfectly tailored for you without having you waste time commuting to get the quality you deserve.

Getting Your Custom Shoes

In a world full of fashion trends, adding your own style of elegance is essential. That style can only be applied if you look closely at what you wear.

Here, you got that closer look behind shoemaking and understood how leather shoes are made, and most importantly, knew all about shoe lasts so you can select your favorite footwear with ease.

You can start here and indulge yourself with the custom-made shoe collection from ADORSI, where you'll different footwear that is beyond compare.