Nowadays, it's all about ready-to-wear (RTW) shoes and the cheap fads and trends that accompany them. Bad quality and wearability are key identifiers of these shoes!

Some people believe men can wear anything. Nevertheless, fashion-conscious gents defy these concepts by opting for high quality and carefully tailored products with timeless styles bespeaking their elegance and individuality.

Such men are prudent enough to invest in truly unique footwear that's known for its longevity and durability. Moreover, such footwear is custom-made and when made of the right material, it can be resoled time after time plummeting the cost-per-wear considerably!

This attributes to the worth of custom-made shoes, but it's not only that! When you have full knowledge of the process, you'll really appreciate different types of custom-made shoes (such as bespoke footwear) even more!

Today, this article will unveil the secret of the custom-made shoe process. Take a look at the shoe making world from behind the scenes!

Why Custom Footwear is of Prime Significance?

The merits of customized shoes are myriad. The overly overt benefit is that this type of footwear is custom fit, i.e. it fits like a glove that was made with you in mind. The custom-made shoe making process bestows durability, flexibility, and unparalleled comfort upon its shoes.

This style of shoe is also meant to be for you, to accommodate your lifestyle, to befit your unique style, and complete your carefully curated wardrobe.

For instance, if a casual outing is your thing, perforated casual footwear is your perfect go-to. However, if you are a regular at formal occasions, fine English footwear such as Oxfords will accentuate your dapper look. Yet, if you want something that goes both ways, there's a wide range of versatile pieces.

Custom shoe wear is an asset to the day-to-day life of every gentleman. To exemplify, the shoe wear is:

- Truly bespeaks your preferences and individual style.

- Substantially boosts your daily performance as it's molded after each foot.

- Perfectly synonymous with unrivaled coziness.

- Carefully crafted with exquisite, unparalleled details by expert artisans.

- Specially made to cater to each and every customer's needs (read this guide to know the sole difference of originality between traditional and custom shoes).

Planning Your Personal Shoe wear Design

Before heading to your dress shoe store, you need to carefully opt for a design that bespeaks your elegant personality because your road companion shouldn't only be the ideal snug for your feet, but also your fashion statement screaming your unique taste and personality.

Thus, you should portray the perfect design in your head by opting for an immaculate style, premium materials, and the most comfortable shape. Only then your bespoke shoemaker will have the full picture and the perfect portrayal of your desired custom-molded shoes.

But what if you don't have a particular design in mind? Simple! Just take a glance at catalogs or brochures to figure out your favorite type of footwear. You can also examine your wardrobe and decide if you desire a similar pair of shoes or if there's a missing piece that will add flair to your wardrobe!

Since different occasions require different styles, you can opt for a variety of styles to perfectly befit that specific setting. To illustrate, you can crave shoe wear solely crafted for white-tie events! Or maybe you need casual handmade shoes for daily usage to provide you with the needed durability and reliance.

So Custom Made Shoe Process: What Is That?

The custom shoe making process is extensively detailed and excessively long. To attain the epitome of fine dress shoes, an adept shoe cobbler with vast knowledge is a requisite.

The custom-made shoe process has the following steps:

- Measurements & Styling

- Lasting

- Pattern Cutting

- Assembling the Shoe

- Final Craftsmanship

- The Shoe Room

1. Measurements & Styling Customization

The magic begins to unfold here. The major juxtaposition between ready-made shoes and custom-molded shoes is accentuated in this stage. The reason behind that is ready-made shoes are standard size, whereas custom fit is modeled with your feet in mind.

You may wonder why standard sizing never gets your size right. Standard size varies from one manufacturer to another since various lasts render different sizes. Hence, men with wide feet have to purchase longer shoe wear. The same applies to men who have fleshy, slim, or bony feet as they tend to purchase uncomfortable shoe wear.

You should come wearing the socks you would wear with the custom fit, preferably dress socks, so the footwear fits like a glove. The adroit shoemaker starts to take measurements in centimeters rather than inches as the former is more accurate when it comes to small measurements with a little-to-no margin of error.

The skilled cobbler also deploys a strip of tape to measure the length, so the shoes would perfectly fit any curve or medical condition. The sizing gets even more accurate down to protrusions or calluses using the pedograph with ink.

Furthermore, after taking the measurements, men opt for their desired material, basic leather for instance. Here, men get tested for sensitivities to any of the materials.

2. Last Making

Lasts can be defined as the plastic or wood base that acts as an exact replica emulating each peculiarity of your right and left foot shape. The whole shoe manufacturing process begins with the last and ends with it.

The shoe is modeled around the last. Then, the last is put inside the finished shoe to ensure it's a perfect fit! It's not a mold that you're supposed to fit in, but it's molded after you!

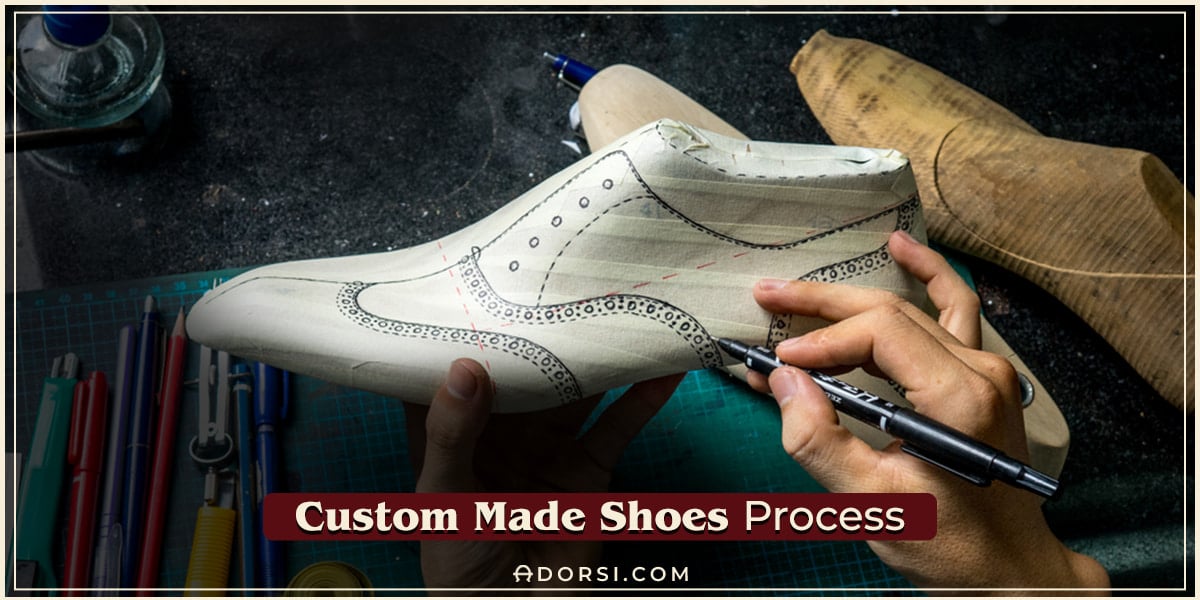

3. Pattern Cutting

It's the stage where the talent of the Shoe Cutter really shines! The artisan starts by cutting a paper pattern to fit the customer's desired style. The pattern usually encompasses vamp, cap, tongue, and quarters.

With finesse, the seasoned artisan turns the paper into the beginning of custom fit by opting for the finest leather considering pliability and weight.

4. Assembling the Footwear

Here, the Cutter hands down the last, patterns, and chopped leather to the Closer. The Closer assembles all the pieces by sewing them together to form the finished shoes, precisely the uppers.

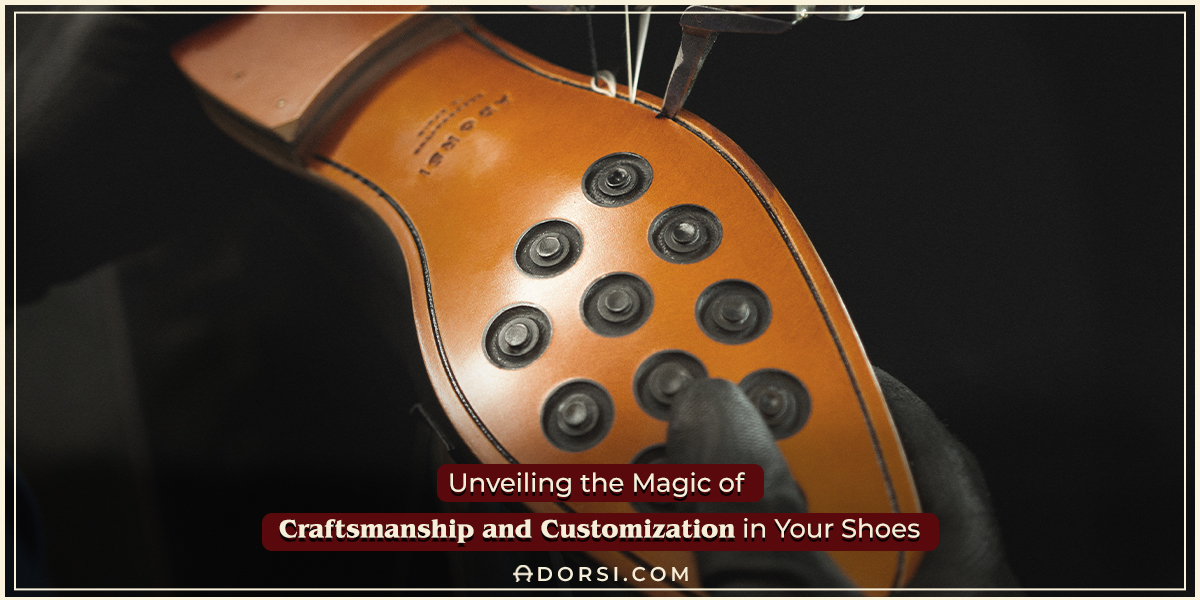

5. Final Craftsmanship

With immense passion and mastery, the custom craftsman adds the finishing touches.

During this stage, the craftsman will put toe and heel stiffeners to create the insole. Then, the insole with rubber ridge on it is temporarily adhered to the lasts, so that welting can be done, whether Goodyear Welt or Blake construction, as per the request of the client.

Tracing its history to 1872, Goodyear welt is the most sophisticated stitching method that adds to the shelf life of the footwear as the whole sole can be replaced with a new one. As a general rule of thumb, fancy footwear always comes with welt stitching. Then, after lasting the shoe upper, it gets strained and attached to the sole.

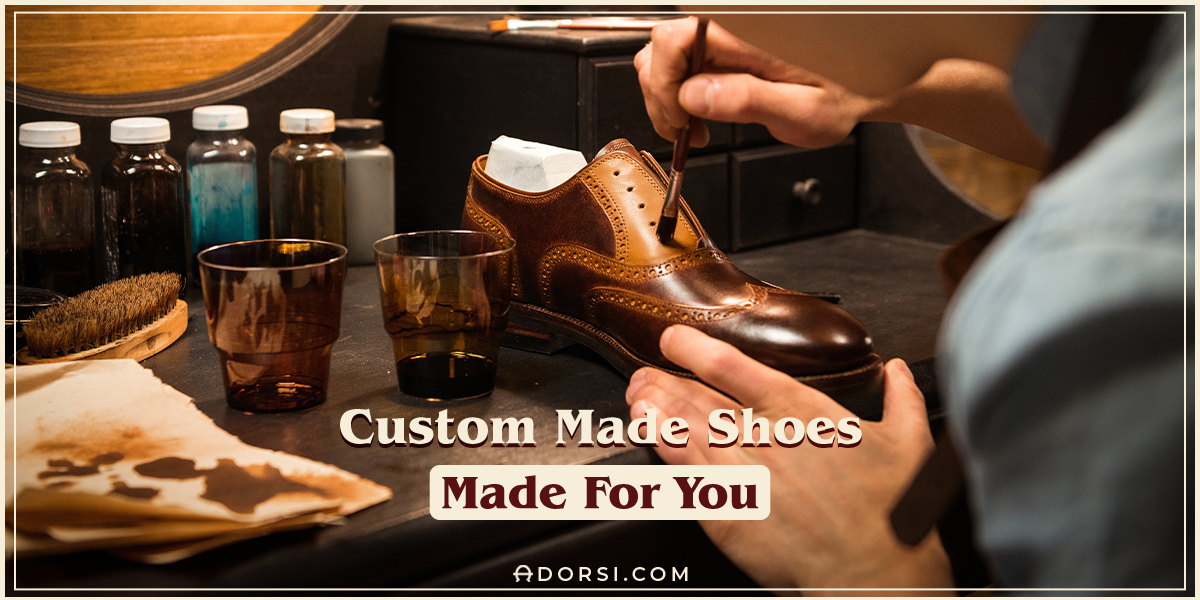

6. The Shoe Room

The Finisher takes over this assignment. He starts by carefully removing the last. Then, he polishes any minor blemishes and cuts any extra threads, so the footwear transforms into a high-end product!

Are You Ready to Get Shoes Made Only for You?

Indeed, the shoe manufacturing process is very intriguing. It hosts a myriad of detailed steps from measurements and styling to the shoe room, accentuating the fineness and precision of such a delicate process as every step is assigned to an expert.

After seeing the sophisticated but fun ride that bespoke shoe wear goes through, are you willing to embark on that wild journey that ends with footwear pampering your feet?

Frequently Asked Questions (FAQs)

1. What to look for in the design of a shoe?

When summoning your inner artist to design your footwear, there are a few things that you should bear in mind, such as the heel elevation, arch structure, excessive cushioning, tapering toe boxes, toe spring, and rigid soles which are normally found in mass-produced footwear.

You may wonder why the aforementioned are so problematic! Well, they leave unwanted medical issues behind! For example, heel elevation impairs normal gait taking away the natural arch support, whilst tapering toe boxes induce deformities, such as hallux limitus and rigidus!

2. Where are bespoke shoes made?

In Spain, of course! It's ADORSI's bespoke shoes that scream every possible fashionable style! Contemporary, classy, and dapper are what Adorsi is all about.

When mass-produced shoe factories churn out mass-produced shoe wear all over the world with their cheap fads, opt for the custom footwear that will eloquently express your individuality and style as the shoemaker exerts an unstinting effort to carefully make every detail.